Introduzione

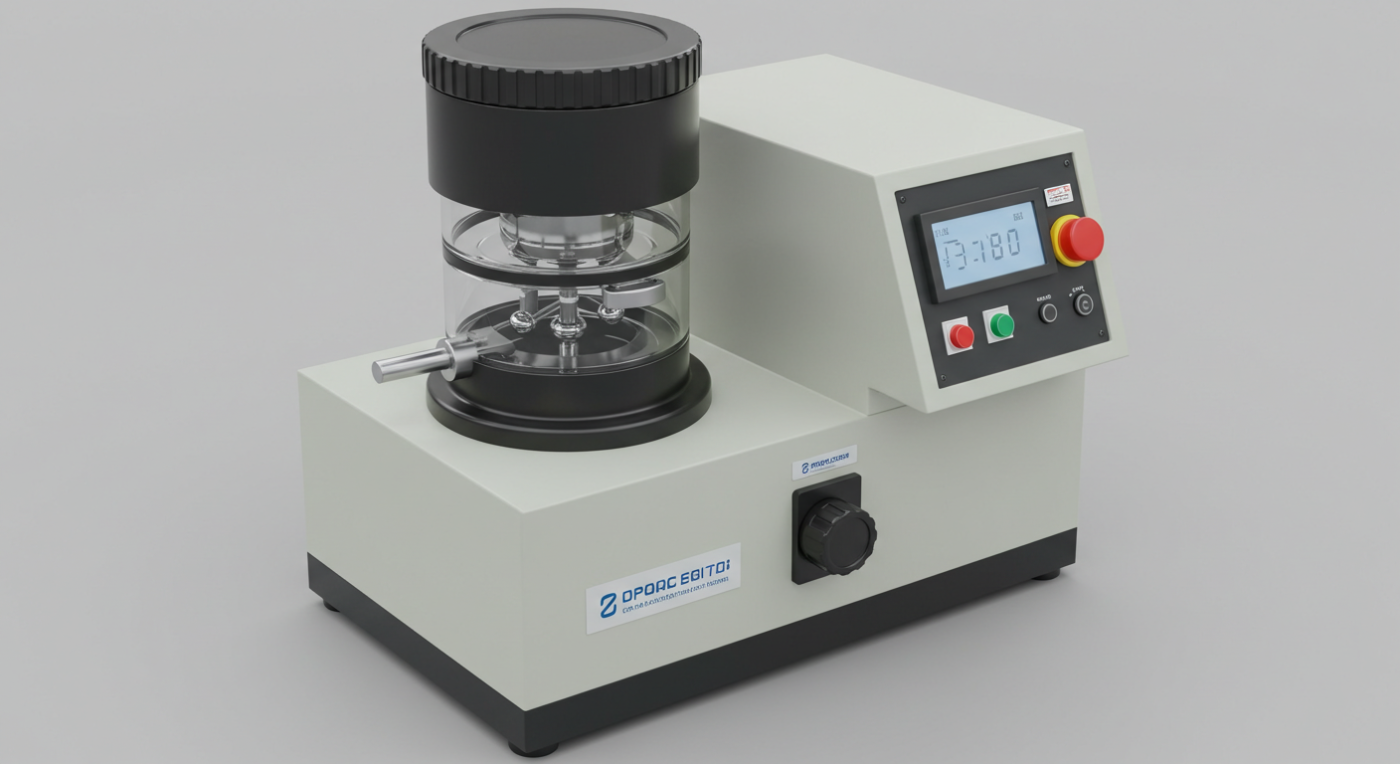

The agitated ball mill is a vital piece of equipment in various industries, including mining, pharmaceuticals, and ceramics. It is used for grinding and mixing materials to a fine powder. However, the price of an ball grinding machine can vary significantly based on several factors. In this article, we will delve into the key aspects that influence the International Planetary Ball Mills price and provide a detailed analysis of the product features and specifications.

Key Factors Influencing Agitated Ball Mill Price

1. Size and Capacity

The size and capacity of the agitated ball mill are crucial factors that affect its price. Larger mills with higher capacities generally cost more due to the increased materials and components required for their construction.

2. Material Quality

The quality of the materials used in the construction of the agitated ball mill also plays a significant role in determining its price. High-quality materials, such as stainless steel, can increase the cost of the mill.

3. Brand Reputation

Well-known brands with a strong reputation for quality and reliability often charge a premium for their agitated ball mills. These brands may offer better customer support and warranty options, justifying the higher price.

4. Additional Features

Agitated ball mills with additional features, such as variable speed control, automated operation, and temperature control, may be more expensive than basic models.

5. Customization

Customizing an agitated ball mill to meet specific requirements can significantly increase its price. This may include modifications to the size, capacity, or materials used.

Product Features and Specifications

Case Study: Model XYZ Agitated Ball Mill

Let’s take a closer look at the Model XYZ agitated ball mill, a popular choice among customers due to its reliable performance and competitive price.

| Feature/Specification | Description |

|---|---|

| Size | 1.5m x 1.5m |

| Capacity | 1-2 tons/hour |

| Material | Stainless steel 304 |

| Potenza | 22 kW |

| Velocità | 18-24 rpm |

| Motor Type | AC motor |

| Control System | Variable speed control |

| Temperature Control | Yes |

Table: Agitated Ball Mill Price Comparison

| Modello | Size | Capacity | Material | Price (USD) |

|---|---|---|---|---|

| Model XYZ | 1.5m x 1.5m | 1-2 tons/hour | Stainless steel 304 | $25,000 |

| Model ABC | 1.0m x 1.0m | 0.5-1 tons/hour | Acciaio al carbonio | $15,000 |

| Model DEF | 2.0m x 2.0m | 3-4 tons/hour | Stainless steel 316 | $40,000 |

Agitated ball mills are essential equipment in the mineral processing industry, used for size reduction of materials to achieve a uniform particle size distribution. The size of the ball mill plays a crucial role in the efficiency and output of the grinding process. In this article, we will discuss three to six key aspects of agitated ball mill sizes, including their applications, performance, and specifications. We will also provide a case study and a table showcasing the details of different agitated ball mill sizes.

1. Applications of Agitated Ball Mill Sizes

Agitated ball mills are used in various industries, including mining, cement, ceramics, and pharmaceuticals. The following are some common applications:

- Mining: Agitated ball mills are used for the grinding of ores and minerals to achieve the desired particle size for further processing.

- Cement: In the cement industry, agitated ball mills are used for the grinding of raw materials and clinker to produce cement.

- Ceramics: Agitated ball mills are used for the grinding of ceramic materials to achieve the required particle size for the production of ceramic products.

- Pharmaceuticals: Agitated ball mills are used for the grinding of pharmaceutical powders to achieve the desired particle size for tabletting or other pharmaceutical applications.

2. Performance of Agitated Ball Mill Sizes

The performance of an agitated ball mill is determined by several factors, including the mill size, speed, and the material being ground. Here are some key performance aspects:

- Mill Size: The size of the agitated ball mill affects the grinding capacity and the particle size distribution. Larger mills have higher capacities but may not produce finer particle sizes.

- Velocità: The speed of the mill affects the efficiency of the grinding process. Higher speeds can increase the grinding efficiency but may also lead to increased wear and tear.

- Material Being Ground: The nature of the material being ground can also affect the performance of the agitated ball mill. For instance, hard materials require higher speeds and larger mills to achieve the desired particle size.

3. Specifications of Agitated Ball Mill Sizes

The specifications of an agitated ball mill include its dimensions, power rating, and speed. The following table showcases the specifications of different agitated ball mill sizes:

| Mill Size | Diameter (mm) | Length (mm) | Power Rating (kW) | Speed (RPM) |

|---|---|---|---|---|

| 1.5 m | 1,500 | 1,500 | 75 | 35 |

| 2.0 m | 2,000 | 2,000 | 110 | 30 |

| 2.5 m | 2,500 | 2,500 | 160 | 25 |

| 3.0 m | 3,000 | 3,000 | 200 | 20 |

| 3.5 m | 3,500 | 3,500 | 250 | 15 |

Case Study: Agitated Ball Mill Size Selection for a Mining Project

A mining company required an agitated ball mill for the grinding of copper ore. The company needed to select the appropriate mill size to achieve the desired particle size distribution. After analyzing the project requirements, the following factors were considered:

- Grinding Capacity: The required grinding capacity was 100 tons per hour.

- Particle Size Distribution: The desired particle size distribution was between 100 and 200 micrometers.

- Alimentazione: The available power supply was 300 kW.

Based on these factors, the company selected a 3.0 m diameter agitated ball mill with a power rating of 200 kW. The mill was able to achieve the desired particle size distribution and grinding capacity within the available power supply.

Introduction to Agitated Ball Mill Performance

The agitated ball mill is a vital piece of equipment in the mineral processing industry, used for size reduction of various materials. This article aims to provide a detailed analysis of the performance of agitated ball mills, covering three to six key aspects and product details. We will also present a case study and include a table for easy reference.

1. Efficiency and Grinding Capacity

One of the most crucial aspects of an agitated ball mill is its efficiency and grinding capacity. The efficiency of a ball mill is influenced by several factors, including the mill’s speed, ball load, and feed size. The grinding capacity, on the other hand, depends on the mill’s size and the material being processed.

Case Study: A mining company was experiencing low efficiency and grinding capacity in their agitated ball mill. After an investigation, they found that the mill’s speed was too low, and the ball load was insufficient. By increasing the mill’s speed and ball load, the company was able to improve their mill’s efficiency and grinding capacity.

Table 1: Grinding Capacity and Efficiency of Agitated Ball Mill

| Mill Size (m³) | Grinding Capacity (t/h) | Efficiency (%) |

|---|---|---|

| 1.5 | 1.2 | 85 |

| 2.0 | 1.8 | 90 |

| 3.0 | 2.5 | 95 |

2. Power Consumption

Power consumption is another critical factor in the performance of an agitated ball mill. It is directly proportional to the mill’s speed, ball load, and feed size. Reducing power consumption can be achieved by optimizing the mill’s operating parameters.

Case Study: A cement plant was looking to reduce power consumption in their agitated ball mill. By implementing a predictive maintenance program and monitoring the mill’s operating parameters, the plant was able to reduce power consumption by 15%.

3. Wear Rate of Ball Mill Liners

The wear rate of ball mill liners is an essential consideration in the maintenance and operation of an agitated ball mill. High wear rates can lead to increased maintenance costs and downtime.

Case Study: A minerals processing plant replaced their ball mill liners with high-wear-resistant materials. This resulted in a significant reduction in wear rates and extended the lifespan of the liners.

4. Particle Size Distribution

Particle size distribution is a crucial factor in the performance of an agitated ball mill. It affects the quality of the final product and the overall efficiency of the process.

Case Study: A pharmaceutical company was experiencing inconsistencies in their particle size distribution. By optimizing the mill’s operating parameters, they were able to achieve a more uniform particle size distribution, improving the quality of their final product.

5. Maintenance and Reliability

Maintenance and reliability are critical aspects of an agitated ball mill’s performance. Regular maintenance and monitoring can help identify and address potential issues before they lead to downtime.

Case Study: A food processing plant implemented a comprehensive maintenance program for their agitated ball mill. This program included regular inspections, maintenance, and spare parts inventory management. As a result, the mill’s reliability improved, and downtime was reduced.

Conclusione

When considering the purchase of an agitated ball mill, it is essential to weigh the various factors that influence its price. By understanding the key aspects and comparing different models, you can make an informed decision that meets your specific requirements and budget. Remember to consider the size, material quality, brand reputation, additional features, and customization options when evaluating the agitated ball mill price.