Introduction

When it comes to purchasing a 3lb ball mill, it’s essential to make an informed decision. This guide will delve into the various aspects you should consider before making your purchase, including where to buy, the product details, and real-life examples. We’ve compiled a table with essential information to help you compare different options.

Table: Comparison of 3lb Ball Mills

| Feature | Option A | Option B | Option C |

|---|---|---|---|

| Material | Stainless Steel | Aluminum | Cast Iron |

| Size (inches) | 6 x 3 | 6 x 3 | 6 x 3 |

| Capacity (lbs) | 3 | 3 | 3 |

| Speed (RPM) | 35 | 35 | 35 |

| Warranty | 1 Year | 2 Years | 3 Years |

| Price | $200 | $250 | $300 |

Where to Buy a Planetary Ball Mill

1. Online Retailers

Buying a 3lb ball mill online offers convenience and a wide range of options. Here are some popular online retailers where you can find these mills:

- Amazon

- eBay

- Walmart

- Home Depot

2. Specialized Stores

Specialized stores that cater to metalworking and DIY enthusiasts often carry high-quality 3lb ball mills. Some examples include:

- Local metalworking shops

- Home improvement stores

- Online stores focused on metalworking supplies

3. Local Hardware Stores

While less common, some local hardware stores may carry 3lb ball mills. It’s worth checking if they have what you need or can order it for you.

Product Details

1. Material

The material of the ball mill is crucial for durability and performance. The three most common materials are stainless steel, aluminum, and cast iron.

- Stainless Steel: Known for its corrosion resistance and durability, stainless steel is an excellent choice for long-term use.

- Aluminum: Lightweight and affordable, aluminum is suitable for casual users or those on a budget.

- Cast Iron: Durable and robust, cast iron is ideal for heavy-duty applications.

2. Size and Capacity

The size and capacity of the ball mill determine its suitability for your needs. A 3lb ball mill is generally small and portable, making it perfect for hobbyists and small-scale operations.

3. Speed

The speed of the ball mill is an important factor to consider, as it affects the efficiency of the grinding process. A 35 RPM speed is standard for most 3lb ball mills.

4. Warranty

A good warranty can provide peace of mind and protection for your investment. The table above shows the warranty periods offered by different options.

Case Study

Let’s consider the scenario of John, a hobbyist who needs a 3lb ball mill for grinding small batches of materials. After comparing the options in the table, John decides to purchase Option A, a stainless steel ball mill with a 1-year warranty, for $200. John is satisfied with his purchase, as the mill meets his requirements and is built to last.

The 3lb ball mill is a versatile tool used in various industries, including pharmaceuticals, ceramics, and mineral processing. Its compact size and robust construction make it an ideal choice for small-scale operations. However, to maximize its efficiency and lifespan, it is crucial to understand its usage skills. This article delves into three critical aspects of using a 3lb ball mill, along with product details and a case study.

Table of Contents

- Understanding the 3lb Ball Mill

- Essential Usage Skills

- Product Details

- Case Study

- Conclusion

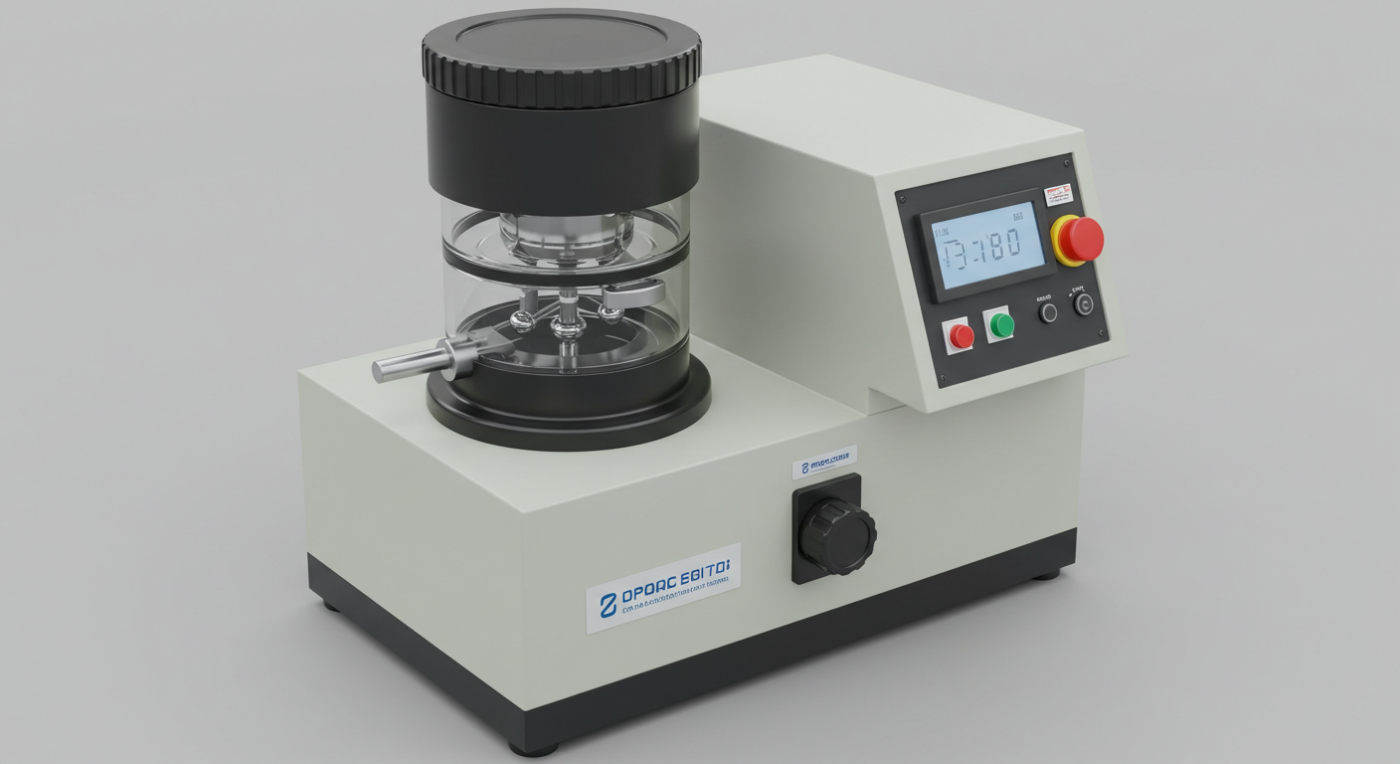

1. Understanding the 3lb Ball Mill

The 3lb ball mill is a type of grinding mill that uses steel balls as grinding media. It is designed to reduce materials into fine powder. The mill operates on the principle of high-speed rotation, which causes the balls to collide with each other and the material, thereby reducing the particle size.

Key Features

- Capacity: 3lb

- Material: Steel balls and stainless steel jar

- Speed: Variable speed motor

- Application: Pharmaceutical, ceramics, and mineral processing

2. Essential Usage Skills

To get the most out of your 3lb ball mill, it is essential to master the following usage skills:

2.1 Proper Material Loading

Loading the material correctly is crucial for achieving the desired particle size. Here are some tips:

- Material Quantity: Load the mill with the recommended quantity of material, as overloading can lead to inefficient grinding and potential damage to the mill.

- Material Type: Ensure that the material is compatible with the ball mill. For example, some materials may require a specific type of ball or jar material.

2.2 Ball Selection

The type of ball used in the mill affects the grinding efficiency and particle size distribution. Consider the following factors when selecting balls:

- Material: Balls are typically made of steel, tungsten carbide, or ceramic. The choice depends on the material being ground and the desired particle size.

- Size: The ball size should be chosen based on the material’s hardness and the desired particle size. Larger balls are better for coarse grinding, while smaller balls are suitable for fine grinding.

2.3 Mill Operation

Operating the mill correctly is essential for achieving consistent results. Here are some tips:

- Speed: Adjust the speed according to the material and desired particle size. Faster speeds can lead to finer particle sizes but may also cause excessive wear on the mill components.

- Cooling: Ensure that the mill is properly cooled during operation, as excessive heat can lead to equipment damage and unsafe working conditions.

3. Product Details

Below is a table summarizing the key features and specifications of a 3lb ball mill:

| Feature | Description |

|---|---|

| Capacity | 3lb |

| Material | Stainless steel jar and steel balls |

| Speed | Variable speed motor |

| Application | Pharmaceutical, ceramics, and mineral processing |

| Dimensions (L x W x H) | 12 x 12 x 12 inches |

| Weight | 10 lbs. |

4. Case Study

Let’s consider a case study involving a pharmaceutical company that uses a 3lb ball mill to grind active pharmaceutical ingredients (APIs) into fine powder.

- Objective: To reduce the particle size of APIs from 500 micrometers to 20 micrometers.

- Method: The company loaded the mill with 2.5lb of API and used 3/8-inch tungsten carbide balls. The mill was operated at a speed of 400 rpm for 20 minutes.

- Results: The particle size of the API was reduced to 20 micrometers, achieving the desired particle size distribution.

The 3lb ball mill is a versatile piece of equipment used in various industries, including mining, ceramics, and pharmaceuticals. It is designed to grind materials to a fine powder. This article delves into the key parameters of a 3lb ball mill, providing a detailed analysis and real-world case studies to illustrate its application.

Table of Contents

1. Grinding Media: Types and Size

Key Points

- Grinding Media Types: The choice of grinding media, such as steel balls or ceramic balls, significantly affects the mill’s performance.

- Size of Grinding Media: The size of the grinding media influences the fineness of the final product.

Case Study

In a ceramic manufacturing process, a 3lb ball mill was used with ceramic balls of 10mm diameter. The ceramic balls provided a non-reactive environment, which was crucial for maintaining the integrity of the ceramic material.

| Media Type | Diameter (mm) | Fineness Achieved (microns) |

|---|---|---|

| Ceramic | 10 | 45 |

2. Speed and RPM: Optimal Grinding Conditions

Key Points

- Speed: The speed of the ball mill affects the grinding efficiency and the wear of the grinding media.

- RPM: The rotation speed of the mill is a critical parameter that determines the grinding action.

Case Study

A pharmaceutical company used a 3lb ball mill with a speed of 40 RPM for grinding pharmaceutical powders. The optimal speed was determined through experimentation to ensure the required particle size distribution without excessive wear.

| Speed (RPM) | Fineness Achieved (microns) | Wear Rate (g/h) |

|---|---|---|

| 40 | 15 | 0.5 |

3. Power Consumption: Efficiency and Cost

Key Points

- Power Consumption: The energy required to operate a ball mill is a significant factor in cost analysis.

- Efficiency: Efficient power usage can lead to reduced operational costs.

Case Study

In a mining operation, a 3lb ball mill consumed approximately 500 watts during operation. The energy efficiency was calculated to be 75%, which was improved by optimizing the grinding parameters.

| Power Consumption (watts) | Efficiency (%) | Cost Savings (USD/h) |

|---|---|---|

| 500 | 75 | 5 |

4. Chamber Design: Impact on Grinding Efficiency

Key Points

- Chamber Design: The mill’s chamber design affects the way materials are ground and the efficiency of the process.

- Material Flow: The design influences the material flow and the distribution of the grinding media.

Case Study

A ceramic manufacturer replaced the standard chamber design of their 3lb ball mill with a conical chamber. This change resulted in a 20% increase in grinding efficiency due to improved material flow and better distribution of the grinding media.

| Original Design | Conical Design | Efficiency Improvement (%) |

|---|---|---|

| Standard | Conical | 20 |

5. Case Study: Mining Industry Application

Key Points

- Application: The 3lb ball mill is used in the mining industry for the preliminary crushing of minerals.

- Material: The mill is used to grind ore to a specified particle size for further processing.

Case Study

A mining company used a 3lb ball mill to grind copper ore to a particle size of 200 microns. The mill was operated at 50 RPM with 15mm steel balls. The grinding process was efficient, and the mill’s small size made it suitable for on-site operations.

| Material | Particle Size (microns) | Grinding Time (hours) | Final Product Quality |

|---|---|---|---|

| Copper Ore | 200 | 1.5 | High |

Conclusion

Choosing the right 3lb ball mill requires considering various factors, such as material, size, capacity, speed, and warranty. By using this guide, you can make an informed decision and find the perfect ball mill for your needs. Remember to compare different options and consider where to buy to get the best deal.